- Cured-in-place Lining (CIPP)

-

Cured in Place Pipe (CIPP) can be used to rehabilitate sanitary sewers, storm drains and pressure pipelines for water, gas and process effluents. Circular pipe from 100-2,700mm and a variety of noncircular pipe such as egg shapes, ovoids, and box culverts can be lined. Lining with CIPP removes the pipe from service for the duration of the installation and reinstatement process so overpumping or provision of an alternate source of supply may be necessary.Prior to lining, the pipe must be cleaned by jetting to remove corrosion debris and detritus. Protruding lateral connections also must be removed. Local repairs may be required where the existing pipe is substantially deformed or damaged. After lining, the service connections or laterals are reinstated and the pipe is returned to service, usually within the same day. Lined water mains must be disinfected before returning to service.CIPP liners of non-woven polyester felt or fibre reinforced fabric are manufactured to fit the host pipe. The liners are impregnated with a polymer resin, which when cured will form a close fitting liner pipe within the host pipe. The liner may be designed with sufficient thickness when cured to sustain the loads imposed by external groundwater and internal service pressure, and by soil and traffic acting on the pipe. The liner is thoroughly saturated with polyester, vinyl ester epoxy or silicate resin using vacuum, gravity or other applied pressure. The resin includes a chemical catalyst or hardener to facilitate curing. The outermost layer of the liner tube is coated with a polymer film to protect the liner during handling and installation. The impregnated liner may be chilled for transportation to maintain stability until installed.

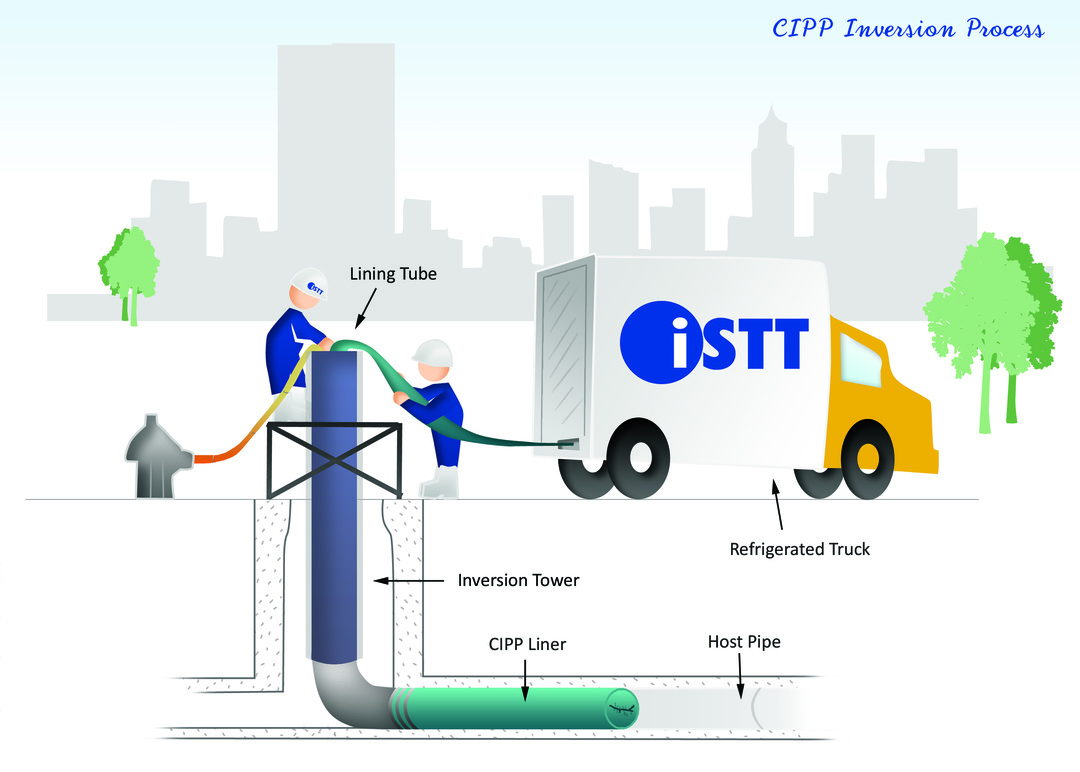

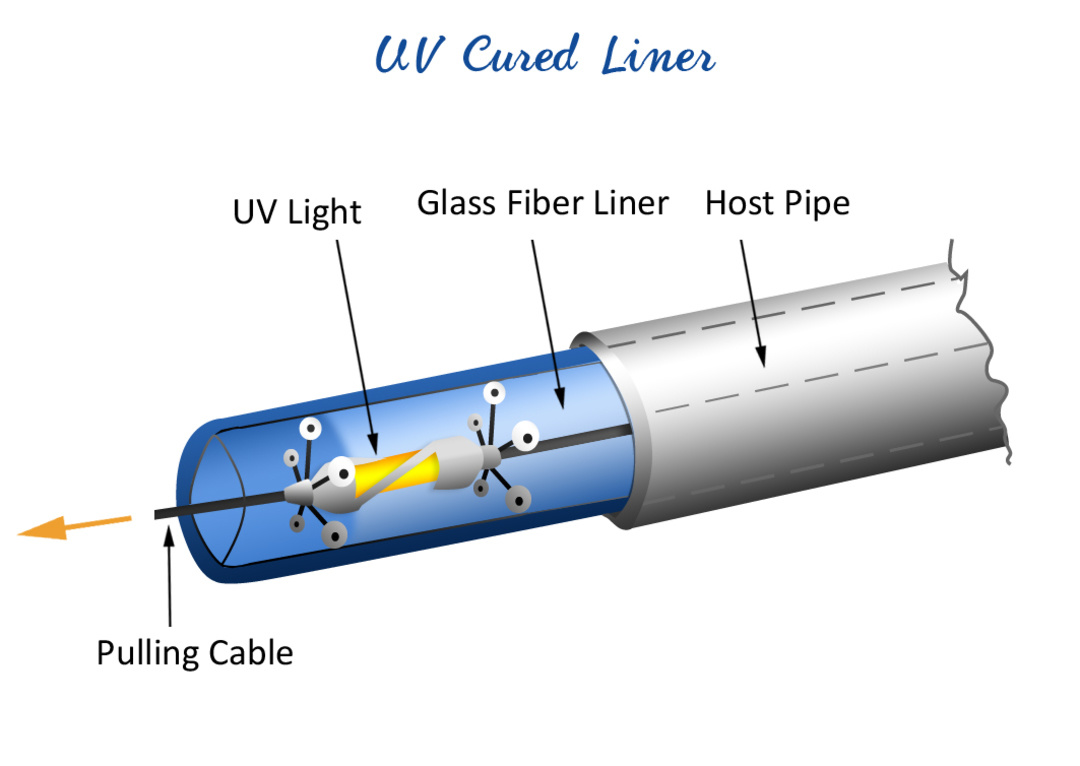

CIPP liners may be installed using the inversion method as shown above. The inversion method employs a scaffold tower or pressure vessel to apply air or water pressure to turn the liner inside out and push it along the host pipe. CIPP liners also may be installed by winching into place through a manhole or specially prepared access point and inflated to come into close contact with the circumference of the existing pipe. The liner is restrained in any intermediate manhole.CIPP liners may be inflated or inverted with air or water pressure. Lengths installed may vary from short sections over a joint or defect, to full length linings typically 30-150m. Lengths of up to 900m have been installed in a single shot.The resin impregnated liner may cure at ambient temperature but the cure is more usually accelerated by application of heat by circulation of inversion water through a boiler, blending steam with inflation air or by pulling through a UV light train. After the pipe has been cured, the liner is cooled and the ends removed flush with the pipe ends, and sealed where necessary. The curing water or steam condensate and the trimmings cut from the liner are removed for safe disposal. A sample of the CIPP may be taken from pipe ends or from a mould cured under the conditions of manufacture for testing and verification that the liner met performance specifications.

The International Society for Trenchless Technology

Cart

Cart