- Sliplining

-

In this replacement application a new pipe of smaller outside diameter than the inside diameter of the existing pipe is inserted (pushed or pulled) within the existing pipe and provides a complete replacement of the structural and flow functions of the existing pipe. This is usually referred to as slip lining. In order to facilitate the insertion of the replacement pipe, the reduction of the inside diameter of the new pipe with respect to the existing pipe is often substantial. The potential reduction in flow capacity may be offset by a lower roughness coefficient for the replacement pipe or the ability to operate the new pipeline at a higher pressure. The slip-lining pipe may be grouted in place within the host pipe depending on the application requirements. In gravity sewer renovation applications, an important advantage of slip lining is that the new pipe can be inserted in segments within the host pipe during active sewer flow – thus avoiding the need for bypass operations that may be necessary with other renovation techniques.

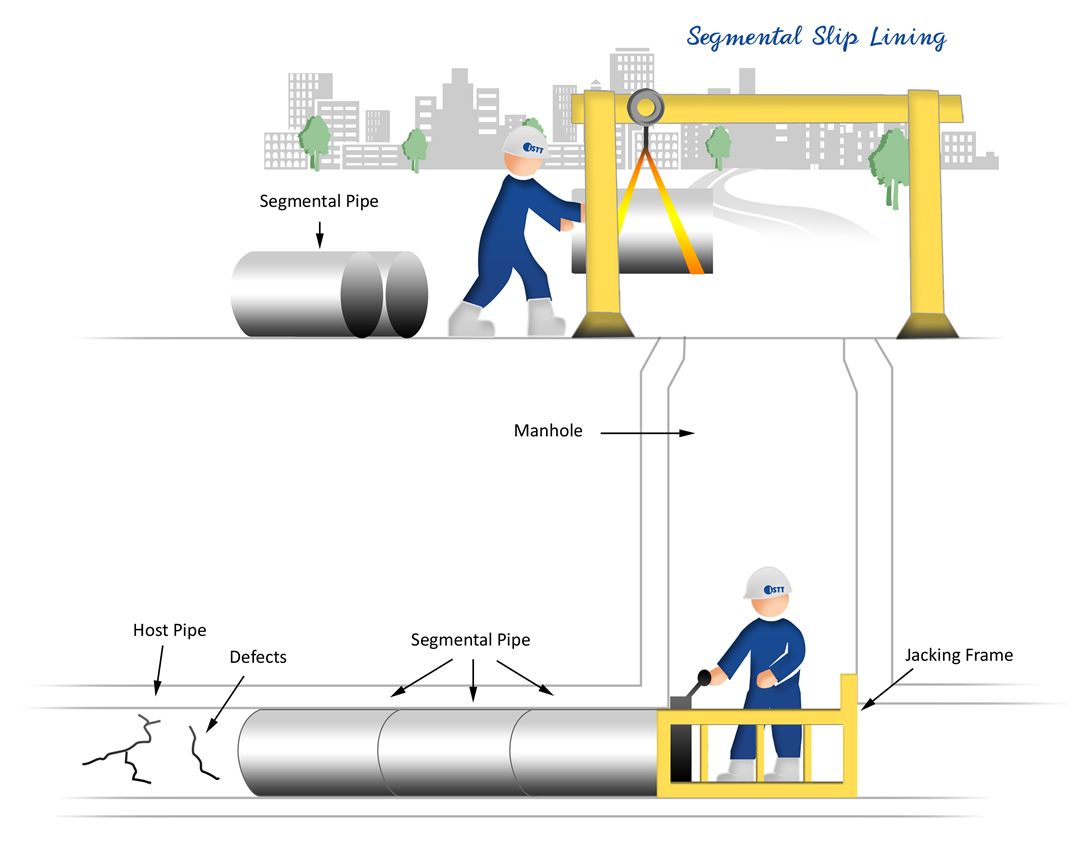

The ideal host pipes for slip lining are straight with no deformities, that is pipes with no or modest bends, no severe protrusions into the pipe, and only modest offset joints. Slip lining may be continuous or segmental. Polyethylene (HDPE and PE) and polyvinyl chloride (PVC) pipes are most commonly used for continuous slip lining circular, non-man entry pipes. The new pipe is laid out above ground and pulled through an excavated pit into the host pipe. The new pipe is winched through the host pipe to an exit pit or manhole. In situations where space for layout of the pipe above ground is limited, the new PE or PVC pipe can be butt-fused during the installation process. After the new pipe has been installed, the annular space between the new and host pipe is grouted. Grout may serve only to restrain the new pipe and transfer load from the existing pipe. The grout may cause the new and host pipe to act as a composite, increasing the pipe’s ring stiffness and its resistance to external hydrostatic loads. The proper selection and application of grout is often the most difficult part of a slip lining job. Grouts that serve only as a filler to restrain the new pipe are relatively low strength grouts with low viscosities. Structural grouts that serve to link liner to the host pipe have higher compressive strengths than grout used only to restrain the liner. Forces on the liner during grouting may be greater than what the liner will encounter during normal service. Excessive grouting pressure could damage or collapse the liner. In addition, floatation forces on the liner need to be taken into account when grouting and means taken to avoid floatation especially in large pipes. These measures can include filling the pipe with water and grouting in stages. Segmental slip lining is typically used to insert Glass Reinforced Plastic (GRP) pipes into circular and non-circular pipes. The size of the host pipe can range from small non-man entry to larger man entry pipes. Segmental liners may be pushed into the host pipe by hydraulic power or winched in place. Concrete and steel pipe with higher compressive strength and stiffness may also be installed as slip liners and present fewer engineering challenges than plastic pipes during grouting.

Also, see "Replacement sliplining" and "Renovation sliplining."

The International Society for Trenchless Technology

Cart

Cart