- Cement / Mortar Lining

-

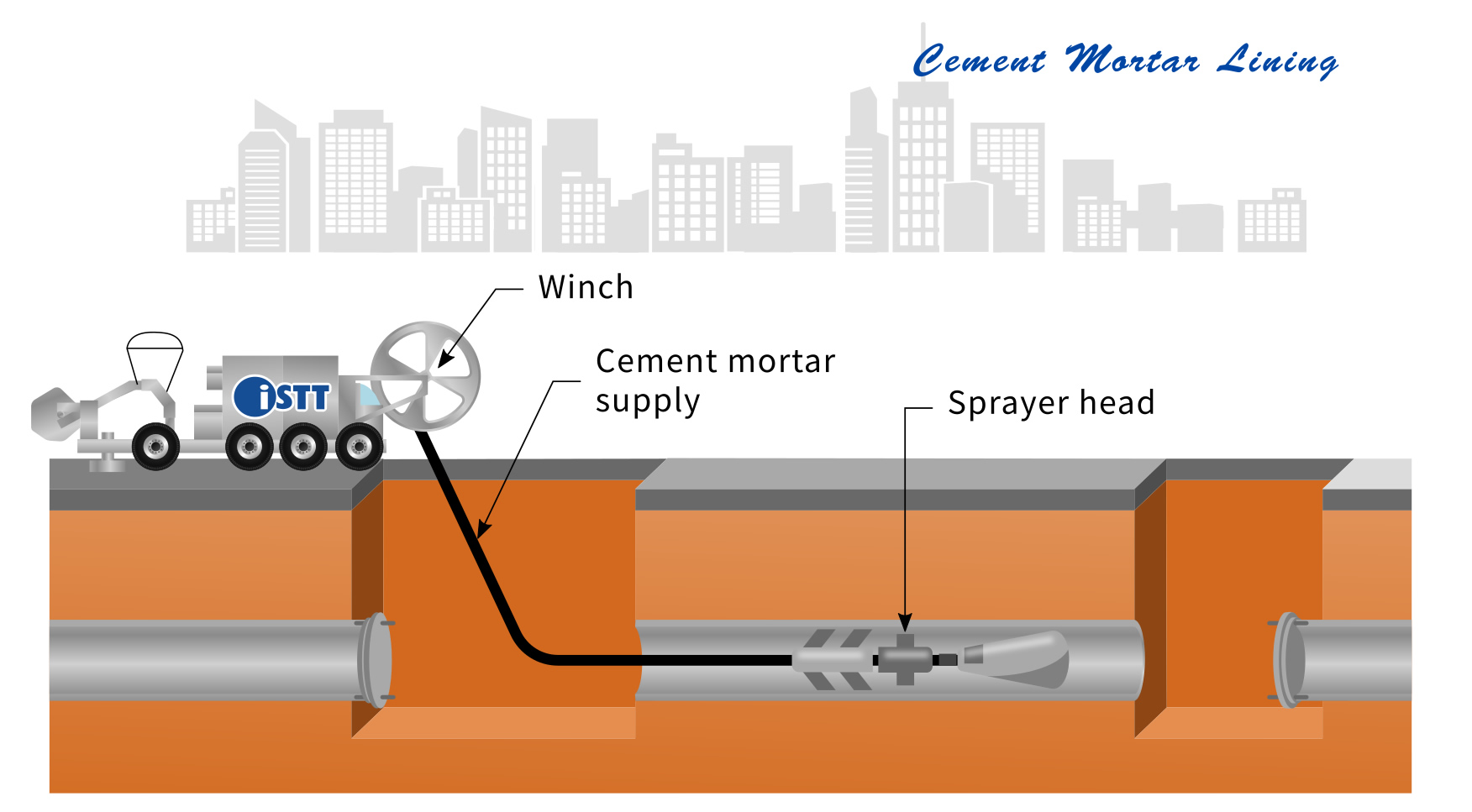

Cement mortar linings (CML), like other spray-on coatings, are used primarily for corrosion protection of small diameter metal pipelines. Cement mortar and concrete linings can also provide structural and leak protection benefits in larger man-entry pipes or tunnels. The host pipe must be thoroughly cleaned of hard deposits, nodules, scale, corrosion and other debris and substantially dry prior to application of the coating to ensure good adhesion between the liner and the pipe wall. Cleaning techniques include high-pressure water jetting, scraping, pigging, rack-feed boring, and mechanically-driven devices such as cutters and chain flails. Some of these techniques are used in combination to help ensure that the host pipe is descaled, cleaned, and dry prior to application of the spray-on lining. Cement mortar provides two benefits. First and foremost, cement mortar linings are highly alkaline and protect the host pipe against metallic corrosion. In addition, the relatively smooth internal surface of the liner reduces hydraulic roughness, improving the flow characteristics of the host pipe. The liner, when bonded with the wall of the host pipe, provides excellent protection against corrosion. In small diameter (non man-entry) pressure pipes, a thin layer of cement mortar is sprayed on using a rotating-head spray machine. The mortar is either fed through hoses from the surface, or in larger pipe applications, the mortar mix is often fed from a down-hole hopper. The speed that the spay machine is pulled through the host pipe determines the thickness of the coating. The spray application is followed by troweling, which is typically carried out by either rotating a spatula fitted to the spay machine or by a tubular shield sized to the internal diameter of the coating, which is pulled through the pipe behind the spray machine.

Cement mortar is the generally the least costly type of coating used to protect small diameter pressure pipes against corrosion, and the easiest to install but is thicker and slower to cure and may cause blockage of utility connections, which must be cleared. In larger man-entry tunnels and pipes, cement-based coatings can be used to create semi or fully structural liners either by incorporating polymers or steel fibers in the mix or by applying the cement-based coating over layers of reinforcing fabrics positioned on the tunnel or pipe walls.

The International Society for Trenchless Technology

Cart

Cart